Specialist in Cummins Mining Engines

Since powering the very first diesel shovel in 1926, Cummins has provided the mining industry with reliable power solutions able to perform in any environment, from 900 feet underground to the harsh Arctic oils sands. Today Cummins products can be found in a variety of mining equipment worldwide, including haul trucks, excavators, wheel loaders, surface miners and mining trucks.

We specialise in delivering high-quality mining service support to our customers that can be tailored to each and every mining site. Our expert service team use the latest tools and processes to provide high quality Cummins engine overhauls, rebuilds, repairs, maintenance and monitoring that ensures maximium uptime and lower total cost of ownership.

Engine Repairs

Through a network of modern, fully equipped field service technicians. Each service engineer is equipped with the latest diagnostic and repair equipment and trained to the highest standard. All repairs are being conducted as per Cummins troubleshooting and repair guidelines.

Benefits

- Full equipped fleet of service vehicle for on-site support

- Each authorised location maintains a full inventory of Genuine Cummins parts and consumables

- Trained and qualified service team

- Work conducted using advanced diagnostic and repair tools that follows Cummins QuickServe service process

Engine Overhauls

Another specialist mining service offering that is delivered by our expert service team is major engine overhauls. From teardown to final inspection our service team look after your equipment.

- Teardown, cleaning of components

- Assessment of engine block and crankshaft to ensure it meets or exceeds Cummins guidelines

- Reassembly of engine using Cummins Genuine parts before final testing

Service Engine Options

Rebuild Engines

Cummins engine rebuilds focus on maximising the uptime, whilst providing you with a rebuilt Cummins engine that delivers reliable and durable performance that will last.

Replacement Engines

Replacement Cummins engines offer a great opportunity for customers to maximise uptime by providing a like for like replacement that can be quickly and easily installed.

Swing Engines

With Cummins swing engines we offer flexible options design to suit the needs of the customer. All options are design to support the customer, ensure prompt availability and maximum uptime.

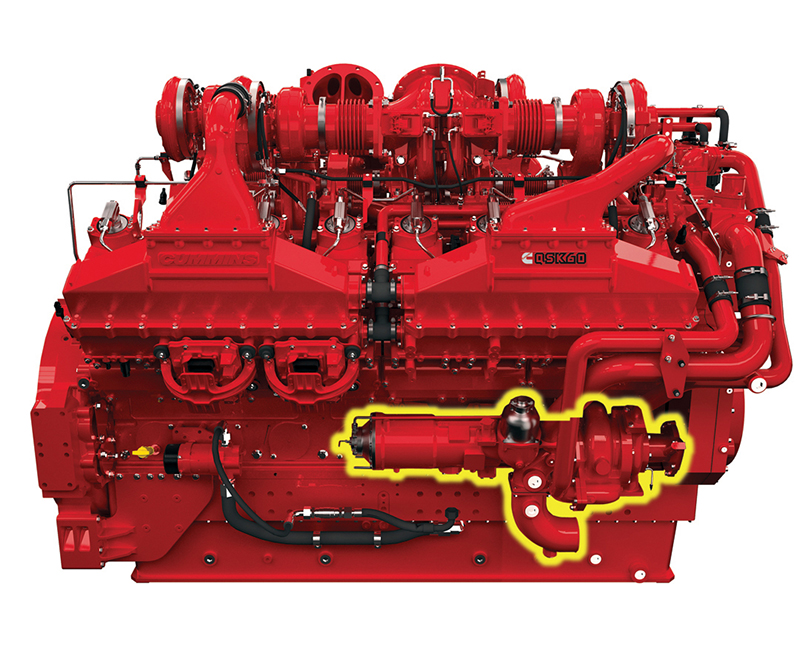

ELIMINATOR

Available on the KTA38, KTA50, and all QSK MCRS engines, Eliminator is a combination full-flow and centrifugal system that incorporates a permanent stainless steel core that eliminates the need for disposable oil filters. It consists of a two-stage filter media system. The first filter screens for particles as small as 20 microns, while a centrifugal separator constantly spins, depositing the heaviest particles on a replaceable liner.

Eliminator uses the oil pressure in the lubricating system to spin the centrifugal separator, there is no additional load on the engine, with no drain on power or fuel economy. This option lowers the cost of operation by:

- Eliminating the recurring cost and maintenance of spin-on filters

- Reducing downtime for filter changes

- Eliminating disposal cost of used filter elements

- Improving filtration and reducing component wear which can extend overhaul periods

- Extending oil change intervals when used concurrently with oil sampling and CENTINEL