Cummins produces the QSK50 dual fuel engine for land-based oil and gas drilling applications. This innovative engine design allows users to power their operations with 100 percent diesel or a mixture of diesel and natural gas.

How Does Dual Fuel Work?

How Does Dual Fuel Work?

In dual fuel mode, natural gas is introduced into the engine’s intake system. The air-to-natural gas mixture is then drawn into the cylinder, just as it would be in a spark-ignited engine, but with a leaner air-to-fuel ratio. Near the end of the compression stroke, diesel fuel is injected and ignites, causing the natural gas to burn.

A dual fuel engine can operate on 100 percent diesel fuel or the substitution mixture of diesel and natural gas, delivering the same power density, torque curve and transient response as the base diesel engine.

Benefits of Dual Fuel Engines

In the oil and gas market, fuel is one of the largest contributors to total cost of operation. Cummins Dual Fuel engines allow for impressive reductions in these costs. The rapid expansion and abundance of natural gas in some areas of the world provides a dramatic cost advantage.

The Cummins Dual Fuel QSK50's integrated controls optimize substitution rate based on operating conditions, to seamlessly and automatically transition between diesel fuel and dual fuel modes. The ability to operate on 100 percent diesel fuel or dual fuel modes provides flexibility based on local availability of natural gas.

Understanding Substitution Rate

Understanding Substitution Rate

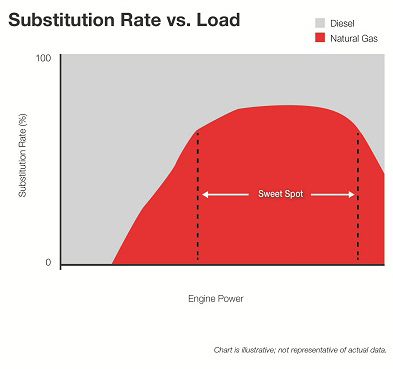

A critical parameter for dual fuel operation is the substitution rate – the portion of total fuel energy provided by natural gas. A maximum substitution rate of 70 percent can be achieved with Cummins Dual Fuel for applications with high load factors.

This figure illustrates substitution rate through the operating range for a typical well servicing application. The sweet spot is where the highest substitution rates are achieved, delivering the greatest reduction in fuel costs.

Fuel and Emissions

There is flexibility with the quality of gas an operator uses. An operator can run on a lower-cost, lower-quality gas at a lower substitution rate, or use a higher-quality fuel at a slightly higher cost with a higher substitution rate.

In the United States, dual fuel engines must meet applicable compression ignition emissions regulations. While specifics may vary, typically an oxidation catalyst to lower carbon monoxide (CO) and non-methane hydrocarbon (NMHC) emissions is required.